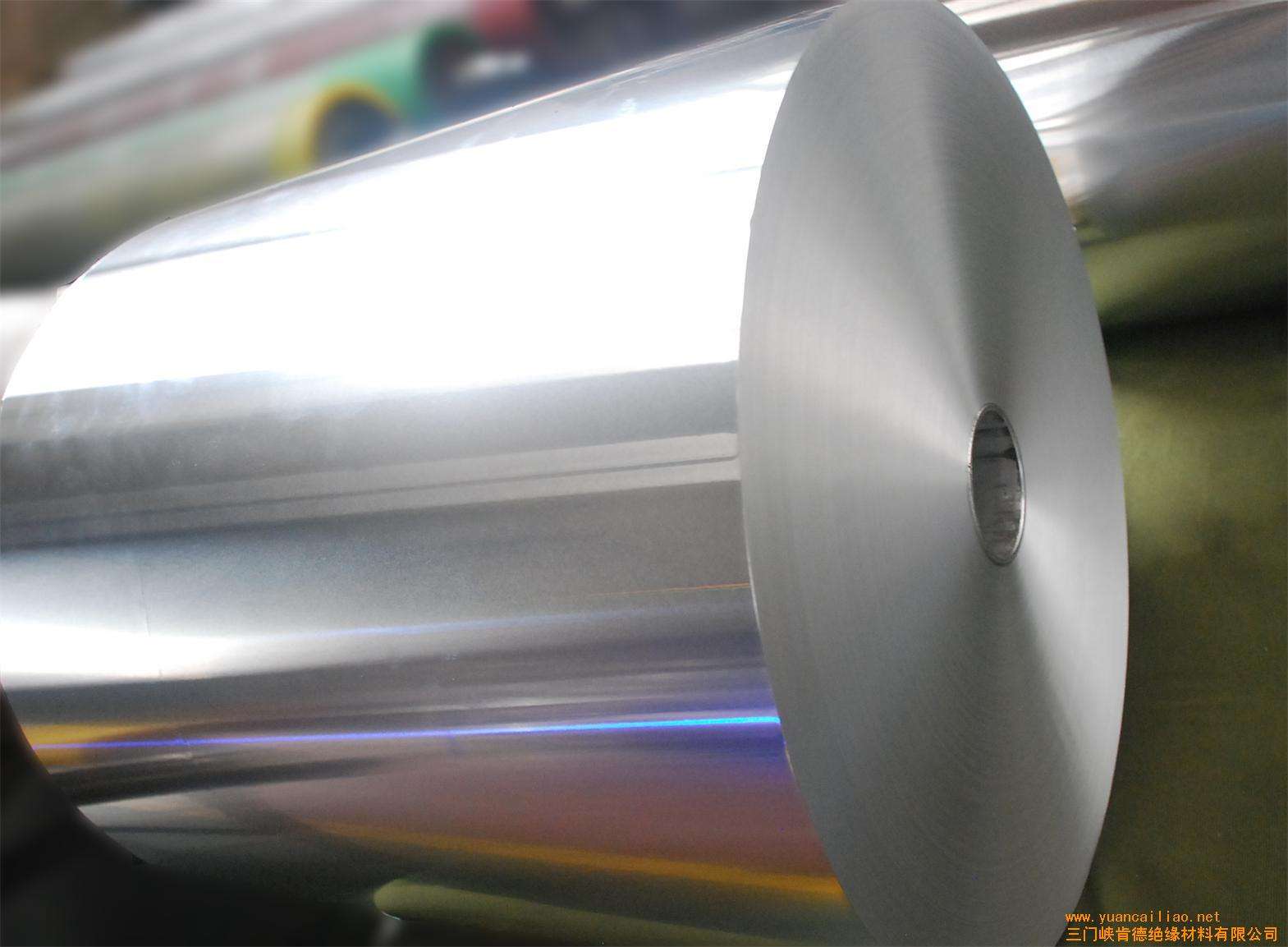

Precoated aluminum foil for air conditioner as a pre treatment material is the key to energy saving, miniaturization and lighting of air conditioning equipment. Its water repellency, corrosion resistance, antibacterial property and formability not only meet the needs of manufacturers to save materials and reduce costs, but also increase added value, extend service life and improve product quality. At the same time, precoated aluminum foil meets the needs of users in terms of energy saving, environmental protection, convenient maintenance and reasonable price. The hydrophilic treatment is to form a hydrophilic film on the surface of the aluminum foil. It has a strong water wettability. Condensed water easily spreads along the surface of the aluminum foil. It does not form a water bridge, but flows downward in the form of a film.

Precoated aluminum foil for air conditioner specification:

Alloy: 8011 H22, 3102 H26, 1100 H22/H24, 1200 H22/H24

Thickness: 0.7mm~0.15mm

Width: 17mm~1200mm

Our precoated aluminum foil for air conditioner the colors are blue and gold. In addition, other colors of hydrophilic foil such as black, milky white and colorless can be coated according to customer requirements. Its unique hydrophilicity can effectively increase the heat exchange rate by 10%~15%. The customized anti-corrosion and antibacterial properties make it widely used in marine vessels, seaside humid heat and chemical environment, as well as household air conditioners, automotive radiators and water tanks. The hydrophilic foil is the main raw material of the heat exchange sheet in the air conditioner, and is widely used in household air conditioners, refrigerators, automobile air conditioners and the like.

Advantages of pre-coated aluminum foil for air conditioning: It can increase the anti-corrosion, anti-mold, and no odor function; the condensed water on the surface of the heat-exchange sheet is evenly distributed on the surface, and will not cause the accumulation of heat-exchange sheets after the formation of water droplets. Blockage, affecting the heat exchange conditions, thereby increasing the heat exchange rate by 5%; because the water has no beads, correspondingly reduces the noise caused by vibration; it can prevent the air-conditioning oxidized powder from being blown into the room and adversely affect the human body, and meets environmental protection requirements.

Recently our 7075 T651 and 6061 T651 have big promotion, please see price update as bleow

Recently our 7075 T651 and 6061 T651 have big promotion, please see price up...+ Details

Is Food Grade Aluminum Foil Toxic?

Aluminum foil is a metal substance and is not toxic. Chalco specializes in t...+ Details

Characteristics and application of coated aluminum foil

Coated aluminum foil is a relatively common material in social production. I...+ Details

Product Features of Medicinal PTP Aluminum Foil

Signi Aluminium is a medicinal aluminum foil manufacturer with excellent qua...+ Details

Medical aluminum foil quality requirements

The raw material used for the production of medical aluminum foil is pure al...+ Details