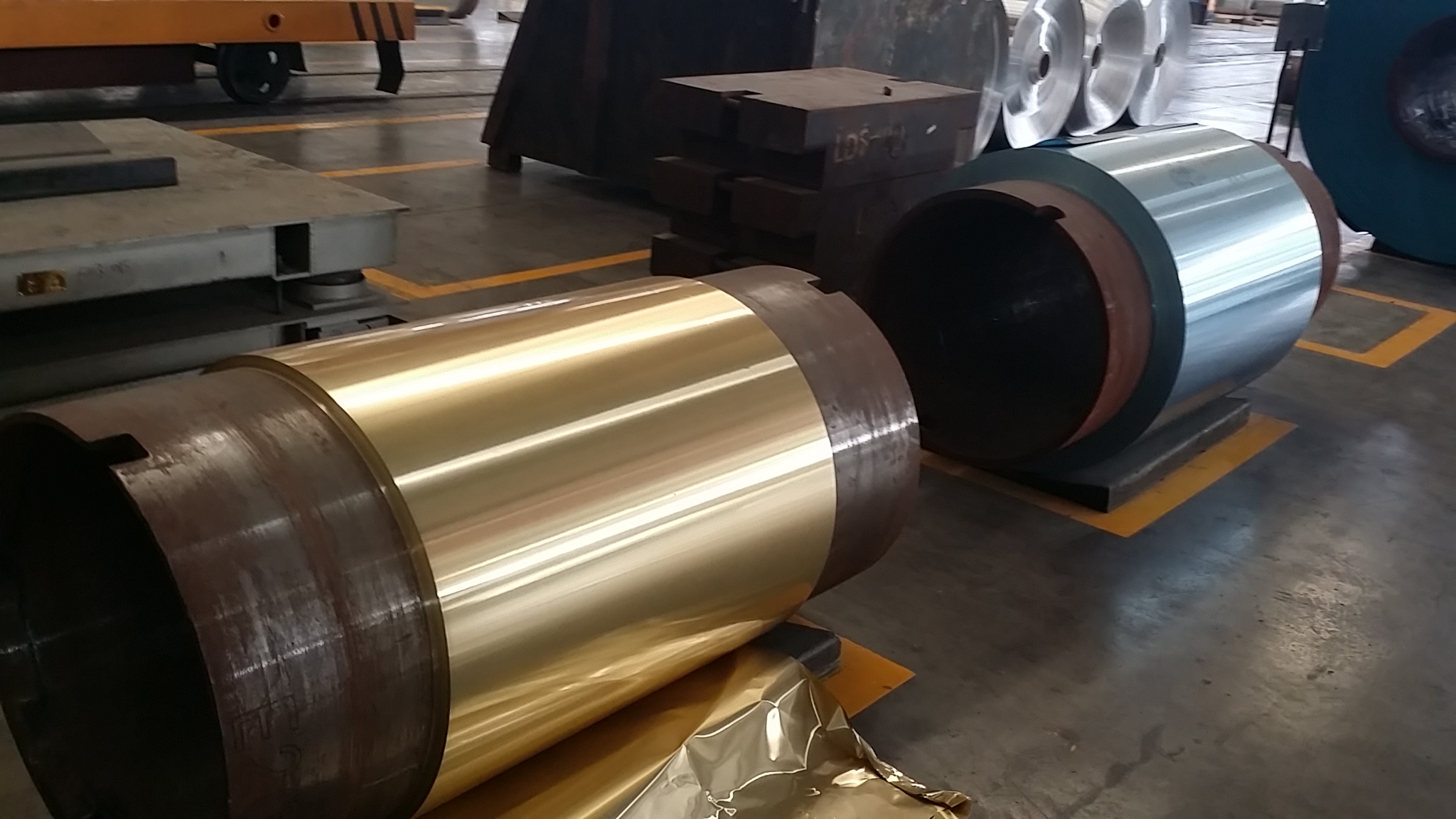

With the improvement of people's living standards and the development of tourism, the market demand for aluminum foil for airline dining boxes and food containers has steadily increased. With the improvement of automation in the forming of food containers and food containers, the higher the requirements for the surface and mechanical properties of aluminum foil are, the thickness of aluminum foil tends to decrease and the strength of aluminum foil tends to increase.

Aluminium foil for dinner box and food containers alloys:

Customers require that the thickness of aluminium foil be thinned and the strength be improved (users used imported aluminium foil from abroad before). They also develop alloy foil, such as 8001 and 3003 alloy. The quality basically meets the requirements of users, while some users use 8006 alloy foil from abroad.

Surface quality of Aluminium foil for dinner box and food containers:

Due to the particularity of the use of aluminum foil for aviation lunch boxes and food containers, the requirements for black wire (strip), pinholes and degreasing on the surface of aluminum foil are particularly high. There should be no obvious black wire and pinholes on the surface of aluminum foil. After annealing, the surface should meet the requirements of grade A of brushing test in the standard.

Recently our 7075 T651 and 6061 T651 have big promotion, please see price update as bleow

Recently our 7075 T651 and 6061 T651 have big promotion, please see price up...+ Details

Is Food Grade Aluminum Foil Toxic?

Aluminum foil is a metal substance and is not toxic. Chalco specializes in t...+ Details

Characteristics and application of coated aluminum foil

Coated aluminum foil is a relatively common material in social production. I...+ Details

Product Features of Medicinal PTP Aluminum Foil

Signi Aluminium is a medicinal aluminum foil manufacturer with excellent qua...+ Details

Medical aluminum foil quality requirements

The raw material used for the production of medical aluminum foil is pure al...+ Details